What is a Top hat beam profile?

A Top hat laser beam is a laser beam whose intensity profile is flat and uniform, with sharp edges where the energy drops rapidly to zero. Such a flat-top energy distribution is called a top hat energy distribution and is highly useful in many industrial laser applications.

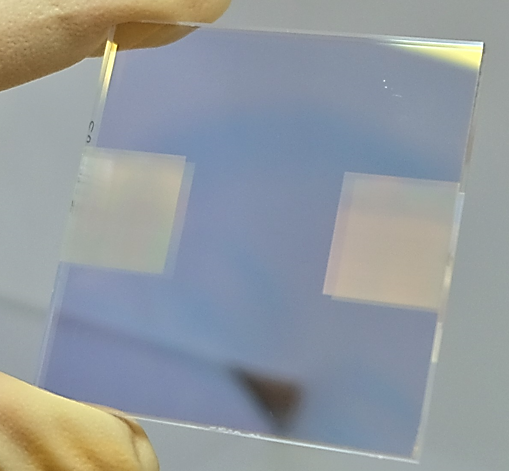

The top hat energy distribution can be a square, rectangle, line, circle or any other shape. The way we can transform a non-top-hat laser beam to a top hat energy profile is by using a top hat beam shaper which is a Diffractive Optical Element (DOE) designed to shape a gaussian, single mode laser beam into a top hat laser beam profile. In this article, we explain how a top hat beam shaper works, and discuss two common examples of top hat application in material processing.

How Does a Top hat laser beam shaper work?

A top hat laser beam shaper works by using a transparent window with an accurately defined surface to modulate the phase of an incoming laser beam. The diffractive element consists of a transparent window with a surface relief structure of varying height. When the laser beam goes through the DOE, the laser is delayed as it passes through areas of greater height, causing a local modulation of the phase. This shapes the beam into a top hat profile at the far field, typically the work plane of a lens in industrial laser systems.

Material processing Top Hat application example: Laser lift-off

In many flat panel processes, such as OLED production, thin, flexible layers must undergo processing steps such as lithography, etching and dicing. Such processes require rigid substrates, so the flexible material is often bonded to a rigid, thick carrier wafer. After processing is completed, laser is used to de-bond the flexible layers in a process known as laser lift off, often employing high power UV lasers to weaken the adhesive.

In such a process, the laser uniformity is critical- non uniform illumination will result in unequal bonding, which may leave contamination, and risk damaging the active layer. Thus, laser lift of benefit by top hat beam shaping, typically to a thin line, top hat laser beam with sharp edges, that is scanned over the surface in strips. This enables uniform and high throughput debonding.

Another Top hat application example: Laser ablation of back oxide in solar panels

Some advanced an efficient Solar panel types, such as PERC solar cells, have oxide or nitride covered back surfaces. To enable charge extraction by contacting electrodes, The oxide/nitride layer must be selectively removed, typically by laser ablation of hole arrays. These holes must be precise, both in dimensions and separation, to provide consistent solar panel performance and quality.

Top hat beam shapers are often used in this application to shape the illumination profile in squares or rectangles with sharp edges and well-defined corners. Such top hat energy profiles enable precise ablation even if the laser is not perfectly stable, since the size of a top hat spot is stable and independent of the energy of the laser pulse, unlike gaussian spots.

Macro processing Top hat application example: Laser shock peening

Laser shock peening is a process were metal is hardened by exposing it to high intensity mechanical shocks created by laser pulses. This process is becoming more critical with the advent of additive manufacturing, as 3D printed metal parts often have internal inconsistencies and stresses that can reduce durability. One of the ways of improving the quality of such parts is by laser shock peening after production.

Top hat beam shapers are used to generate uniform intensity over the area to be hardened by shock peening, ensuring efficient area coverage and uniform hardening of the surface.

TL; DR - Q&A summary

1. What is a top hat beam profile?

A top hat beam profile is an energy profile that has uniform intensity inside the shape, with sharp edges, making the spot a well-defined illumination area.

2. How do you get a top hat energy distribution?

One of the common methods of achieving a top hat energy distribution is by using a diffractive beam shaper. A diffractive beam shaper is a diffractive optical element that can be added to the beam path, and shaped the spot at the work plane into a flat top energy distribution with the desired shape (square, rectangle, circle or line are common).

3. Can you give some typical examples of Top hat application in laser material processing?

Some typical applications of top hat beam shapers include solar panels production and flat panel production. In Solar panels, top hat beam shapers are used to shape the ablation of backside oxide layers, enabling precise contacting. In Flat panel production, diffractive top hat laser beam shapers are used to enable uniform and efficient laser lift off. Finally, in laser shock peening top hat beam shaper are often used to make sure the hardening of the part is uniform and to efficiently cover the area of the workpiece without too much overlapping.