Get free consultation: +972-8-9409687

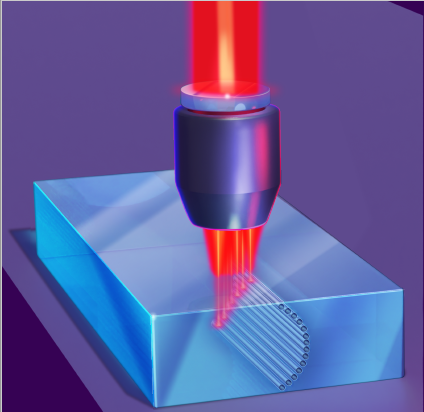

Laser glass cutting is usually done using ultra-fast lasers in the IR, typically around 1um wavelength. The laser energy is focused into the glass, inducing non-linear absorption and plasma filament creation, cracking the glass in a controlled manner. This focused spot is then scanned to create the cut contour. The main laser shaping challenge in laser glass cutting is due to the requirements of the non-linear process. The non-linear effects require high power densities, thus tight focusing to 1-5um spots typically, but such spot have very limited depth of focus, of less than 0.1mm. For thicker glass cutting, laser shaping methods must be used to generate a profile that has a tight spot but with a depth of focus equal to the glass thickness, i.e. 1mm or more, in most cases.

There are various laser shaping approaches to address the challenge of tight focusing over a long depth of focus:

All these methods are more suitable for main glass cuts that define the part, but less suitable for cutting of bevels on the part edge. This requires another secondary process of mechanical grinding to achieve beveled edges, that are critical for both safe handling of glass and glass durability.

There is a method of laser shaping that enables the real time cutting of both glass and bevel. This is a method we call “3D beam shaping” at Holo/Or.

3D beam shaping is a laser shaping method where the focus is split into multiple foci in both the x-y plane as well as in the focal direction, combining the action of a Multifocal DOE with a diffractive beam splitter. The result is a collection of foci that does have to be in a straight line. The foci can be tailored to create a Trapeze or C shape pattern, enabling both main cut, top and bottom bevels to be done simultaniosluy in one laser pass.

A: Laser glass cutting is the process of cutting glass by laser radiation, rather than mechanical or chemical methods. Most laser glass cutting today is done by the filamentation method , using ultra short IR lasers focused to a tight spot.

A: To achieve high quality cutting, the laser needs to be focused to a tight spot , which has a small depth of focus. Laser beam shaping is needed to extend the depth of focus so that it covers the entire glass thickness.

A: 3D beam shaping is a method where a single DOE splits the laser foci in both the X-Y plane as well as along the optical axis (z). This means that the cut path in glass can be not just a straight line.

A:. By Shaping the laser foci in a C or a Trapeze pattern, the laser can now be used to cut the glass while simultaneously creating a bottom and top bevel. This saves time and reduced processing steps.

Design and Manufacture of Diffractive Optical Elements for high power lasers

DESIGN & MANUFACTURE OF DIFFRACTIVE OPTICAL ELEMENTS

Want to discuss your project with us?

Leave your details and

we’ll reach out shortly!