Introduction to Laser Shock Peening (LSP) process

Since the early middle ages, mankind has always struggled to increase the hardness and flexibility of metals, to improve the durability and reliability of metal tools and parts. From the damascus steel smiths through the swordsmiths of medieval japan, the method of cold-working metal by the application of precise mechanical pressure such as hammer blows has a glorious history.

In modern times, this concept has reached its apex with industrial surface hardening using shot peening, where thousands of small lead shot are fired at the metal surface, compressing and hardening the surface , improving the durability. With the advent of high power laser systems, an improved process has been developed, the process of Laser Shock peening.

Laser Peening (LP) or Laser Shock Peening (LSP) is a process in the field of surface engineering, in which a pulsed high-power laser beam is used to generate residual stresses in materials in order to improve their properties in aspect of surface related failures resistance such as fatigue and stress corrosion cracking, or strengthen thin sections and harden the surface of materials.

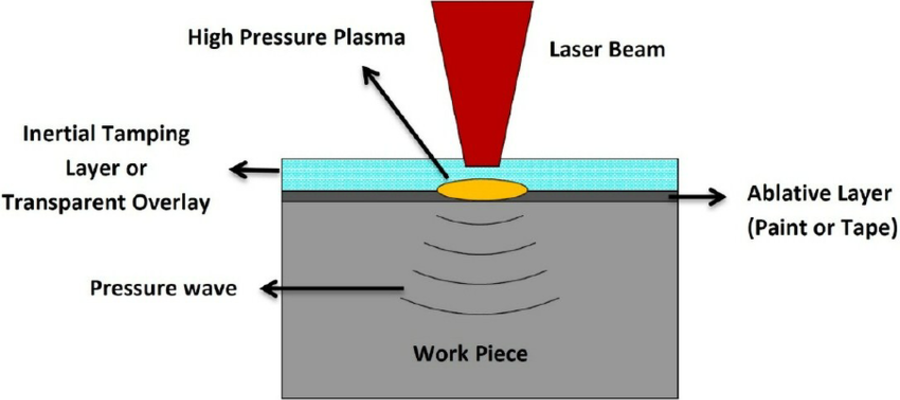

Unlike most material processing applications who utilize laser power for thermal processes to achieve the desired results, LSP is a mechanical process which utilizes momentum of the laser beam. The high-power laser beam strikes the surface of the target workpiece at high rate short pulses.

The beam strikes the metal workpiece surface and immediately evaporates a thin layer of it to a state of plasma which applies shock wave pressure on the target workpiece. Sometimes, an additional thin layer of an opaque overlay material will be placed on the workpiece and so that opaque material will be evaporated instead of the metal. In order to increase that pressure, another transparent overlay or inertial tampering layer is used to capture the plasma, typically – water.

The plasma creates a shock-wave effect reshaping the workpiece surface’ microstructure in the struck point, which in turn creates a chain reaction of expanding and compressing metal which results in deep compressive stresses that extend the life of components.

Market trends

LSP has been used in many industrial applications since the 1990’s including: aeronautics, automotive, power generation, drilling and more, and developments in the field have been aimed at decreasing process costs and increasing throughput to reach other potential markets.

Recent years’ developments in automation and in the laser industry have helped in reducing labor costs and energy costs. The sharp decrease in cost per Watt and the increase in energy availability, now enable shaping the laser beam using beam shaping optics to increase the throughput and further optimize the process.

Laser beam shaping in LSP

There are several different laser beam shaping applications that are applicable for optimizing LSP process:

- Broadband Diffuser (BD) – a broadband diffuser is a special, high efficiency, micro-refractive flat top laser beam shaper generating controlled output shapes, resembling in it’s principle of operation to a microlens array.

- Diffractive Diffuser (HM) – the diffractive diffuser is a Diffractive Optical Element (DOE) designed to generate any freeform output shape with uniform, homogenic and flat top profile from a multimode input beam.

- Diffractive Top Hat (TH) – the diffractive top hat is a DOE designed to generate controlled output shape with flat top energy distribution and very sharp transfer region.

- Diffractive Beam Splitter – the diffractive beam splitter (also known as Multispot) generates any number of output beams with identical characteristics to the input beam, at a controlled arrangement and separations. Such an element can generate an array of >10,000 spots and cover large areas with good uniformity.

Holo/Or offers customized laser beam shaping solutions that can encompass more than one optical function on the same flat element.

TL; DR - Q&A

What is laser shock peening?

Laser shock peening (LSP) is a mechanical process in which a pulsed high-power laser beam is used to modify the surface micro-structure of a workpiece in order to reduce surface-related failures of the material.

What is the laser shock peening process principle of operation?

In laser shock peening, a controlled focused laser beam strikes the workpiece and generates a shock-wave reaction. This shock wave travels through the material and produces compressive residual stresses. Thanks to the process’ mechanical nature (and not thermal), the metal workpiece’s shape and properties are preserved.

What are the applications of Laser Shock Peening?

Laser Shock Peening (LSP) process is used to reduce strains in the material, strengthen thin sections of it or hargen its surface, all to extend the life time of the component. Applications utilizing this process include aeronautics, automotive, power generation, drilling and more

What are the laser beam shaping optics that can improve the laser shock peening process?

The beam shaping optics used for laser shock peening (LSP) process may include either a high-efficiency broadband diffuser, a diffractive diffuser for homogenization of a multimode input beam or a diffractive beam splitter for increased throughout.