Introduction

Stimulated emission depletion (STED) microscopy is a well-known technique for achieving super resolution in microscopy that enables resolving sub-micron details that are smaller than the diffraction limit of the optical system.

Developed to bypass the diffraction limit of light microscopy , which is the main limit to the resolution of traditional light microscopes, it creates super-resolution images by illumination the fluorophores in a ring-like (donut) illumination pattern that depletes the fluorescence from the outside area of the donut, thus minimizing the area of illumination at the sample focal point and enhancing the achievable resolution for a given system.

By using the non-linear response of the fluorophores, STED forces the excited fluorophores at the donut profile to emit at a longer wavelength that is then optically filtered out. Only the fluorescence from a small, sub-diffraction limit region is left, enabling super-resolution.

STED Microscopy principle of operation

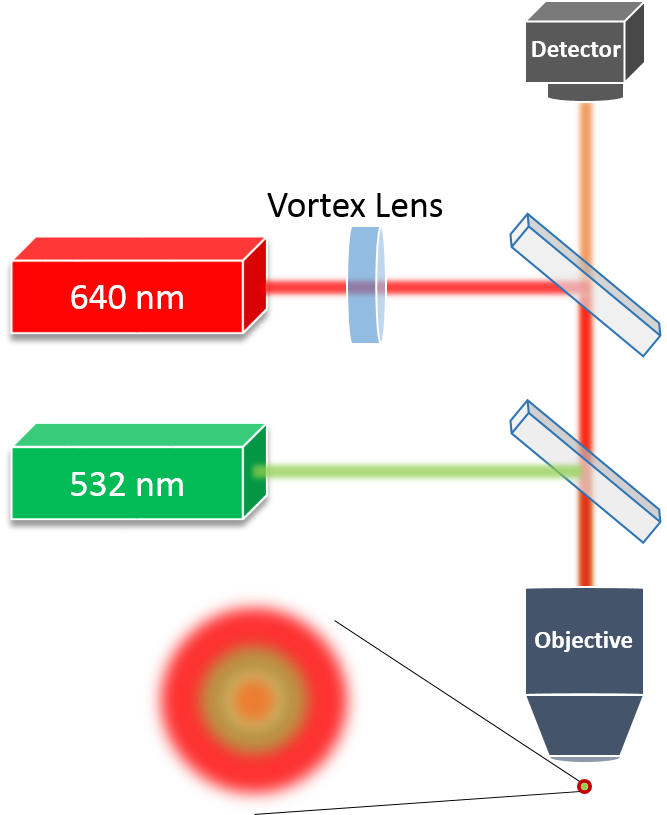

Typical STED systems include two independent optical channels – one for the long wavelength (red) depletion laser and another for the short wavelength (green) excitation laser. Both channels are combined into the same optical path by dichroic mirrors and are then focused by an objective on a sample. Fluorescent light reflected from the sample goes to a detector. Figure 1 describes this setup schematically

The excitation channel is focused by the objective, while the depletion channel is propagated through a vortex phase plate, otherwise known as a Vortex Lens (VL), before it is focused by the objective. The vortex plate adds a spiral wavefront to the incident Gaussian beam in order to convert it into a donut-shaped beam at the focal plane of the objective. The resulting donut shaped beam at the focal plane shares the same optical properties as a Gauss-Laguerre 01 laser mode.

The vortex laser beam in the STED system, i.e. the depletion laser, can be easily generated using a single vortex plate diffractive optical element (DOE).

Overview of Diffractive Optical Elements

DOEs are micro-optical window-like phase elements designed to modify the phase of the light that propagates through them, and create various shaping functions. The main optical functions achievable using DOEs include multi-channel beam splitting, spatial beam shaping and beam focal shaping. Amongst the spatial beam shapes achievable by DOEs are also ring and donut shapes such as the vortex plate DOE used in STED systems.

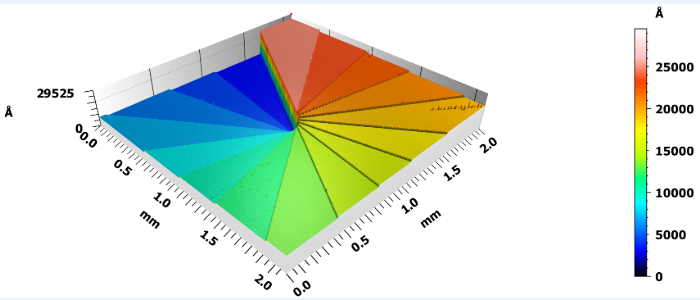

The main fabrication processes of DOEs consists of several repeating steps including photoresist wafer coating, followed by direct UV lithography, etching directly into the Fused Silica substrate and repeat to create a binary pattern microstructure at the surface of the mm scale thick optical window. In order to achieve optimal optical efficiency, it is often recommended to apply up to 4 lithography steps, creating 16 levels microstructures. The last step in the DOE manufacturing process is deploying an anti-reflective coating layer. Figure 2 shows an actual diffractive structure of a 16-level vortex plate generating an optical vortex beam, measured by an optical profilometer.

Thanks to this production process, DOEs provide perfect angular accuracy with extremely low manufacturing tolerances. They are flat, thin and easy to integrate into any opto-mechanical design. On top of these mentioned advantages, Fused Silica made DOEs have outstanding laser damage threshold, surface deviation, micro roughness, and mechanical properties. In many cases, DOEs present a much more cost-effective beam shaping method then their refractive counterparts, frequently demanding complex electro-opto-mechanics, making DOEs a more robust solution when it comes to lifetime value.

STED microscopy, being a technique for measuring submicron structures, requires the system to be highly precise and accurate, otherwise overall performance may be severely affected. That, with all the aforementioned advantages, as well as the fact that Holo/Or’s vortex plates are polarization insensitive who do not require rotation alignment, is why they pose the perfect solution for STED systems.

Holo/Or offers a wide variety of vortex plate DOEs. to calculate the ring and hole diameter of the vortex plate, Holo/Or created this optical vortex calculator to aid our customers in choosing the part fitting their needs.

TL; DR - Q&A

What is STED microscopy?

Stimulated Emission Depletion (STED) microscopy is a technique used to enable super resolution imaging able to detect sub-micron details.

What is the operation principle of a STED microscope?

STED systems use two independent optical channels combined into the same optical path and focused by an objective on a sample. The depletion channel, before being focused by the objective, is propagated through a vortex plate which converts the beam profile into a donut-shaped beam at the focal plane of the objective.

How to generate a donut-shaped beam?

A diffractive vortex plate generates a donut shaped beam with controlled ring and hole dimensions.

What are the advantages of a diffractive vortex plate in a STED microscope system?

Diffractive vortex plates, like all diffractive optical elements, are flat, thin and lightweight. They provide perfect angular accuracy with extremely low manufacturing tolerances, and when fabricated from Fused Silica windows they have outstanding laser damage threshold, surface deviation, micro roughness, and mechanical properties. Holo/Or’s vortex plates are polarization insensitive thus do not require rotation alignment.