A split laser beam is the output of a beam splitter DOE – an optical component generating an array of beams, often used in various applications including industrial, medical and sensing. This article introduces some innovative applications for a split laser beam in industrial material processing applications

Background: What is a multispot beam splitter? how does one generate a split laser beam

A split laser beam is the result of using a diffractive beam splitter with an incoming laser beam. This creates an array of split beams, each sharing the same intensity profile and other characteristics of the input beam (wavelength, polarization), but with a different angle of propagation. The array has angular separations that are determined by the grating equation, which for small splitting angles gives nearly identical separations. When focused by a suitable lens, this array of beams generates a matrix or line of dots with pre-defined separations and arrangement, whose size is determined by the angular divergence of the laser beam. Such an array of spots can be used to increase throughput in many industrial laser processes.

Use of split laser beams in applications of laser beam machining

An array of beams is useful in many industrial applications, especially laser beam machining and surface texturing.

A single laser beam, while it can be steered easily using setups such as a galvo scanner and an F-theta lens, places inherent constrains on the processing throughput of a laser-based machine. These constraints become more and more evident as laser power increases and cost per Joules, or Watts, goes down. To harness the increasing laser power, the use of a diffractive beam splitter is a must, as no scanning system, not even polygon scanners, can scan fast enough to fully spread the laser power over a large area.

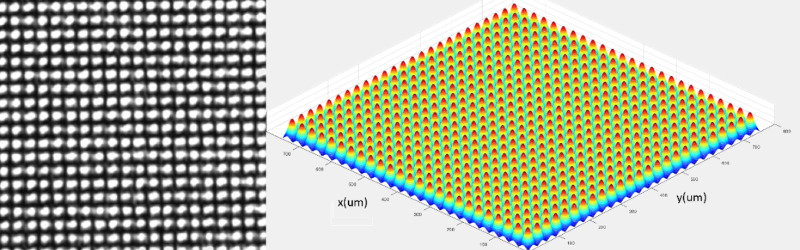

This application limit of scanning systems becomes especially relevant in laser beam machining of periodically structured surfaces, for the purpose of surface functionalization. To achieve realistic processing speeds for industrial purposes, structuring rates of more than 1m2/ min must be reached, meaning millions of spot-sized indentations must be made in a time scale of minutes. No scanner system can scan a single point so quickly and accurately, whereas Holo/Or’s DLITe beam splitter DOE generates a 2D laser beam that patterns an array of thousands of indentations per pulse. The 2D array of spots is then scanned over a surface meant to be functionalized, enabling high throughput texturing at industrial rates. This scanning of the split laser beam can be obtained using stage movement or rolling strip, or alternatively with a galvo or polygon scanner. Since diffractive optics offer full flexibility in terms of the spot matrix shape, it is possible to tailor the area of the laser beam to optimally fit the scanning method and laser parameters.

Use of a diffractive beam splitter in applications of laser beam welding

Laser welding is a rapidly growing application field, and is tightly bound with the e-mobility revolution, as laser welding of battery packs is a critical step in battery manufacturing. A split laser beam is highly useful for laser welding, as multi-KW low cost multimode fiber lasers often have too much power to use in a single spot welding, running into the humping limit of weld speed, where the weld quality becomes unacceptable when power is increased. Often, several weld heads are used with a single such laser to gain throughput, resulting in high costs that are not laser-related. A way to increase the throughput while still using a single welding head is by utilizing a multibeam approach. By correctly splitting the beam and using large field optics, several identical weld lines can be simultaneously processed on the same piece, such as in the case of bus bars or battery tabs. This enables saving in costs compared to methods requiring multiple processing heads.

TL;DR - Q&A summary

What is a split laser beam?

A split laser beam is the output of a diffractive beam splitter DOE, a transparent optical component that makes an input beam into an array of beams with controlled separation angles and power.

Where are split laser beams used?

Split laser beams are used in many applications, from aesthetic fractional skin treatment, through laser material processing and even for machine vision and LIDAR.

why use a diffractive beam splitter in laser machining applications?

A beam splitter DOE can increase throughput in many laser machining applications, by simultaneously processing multiple spots on the surface. This is especially important in laser texturing of large areas, and in other application such as drilling, where thousands to millions of spots must be processed on each workpiece.

How does the beam array approach improve laser welding applications?

Using a multispot beam splitter in laser welding applications with high-powered lasers can help reduce costs by enabling the same throughput as multiple weld heads, using a single weld head to process several weld lines simultaneously.