Background: what is a diffractive beam splitter?

Diffractive beam splitters, or multi-spot elements, are a family of diffractive optical elements (DOEs) that split an incoming laser beam into an array of beams with controlled separation angles.

This splitting can be along a line (1-D splitters), or into a matrix (2-D splitter), including square, hexagonal or rectangular array arrangement. The beam splitter is a periodic phase element, similar to a grating, and is optimized to provide a certain splitting angle at the design wavelength, with maximal efficiency. Since the beam splitter phase is periodic, these elements are not sensitive to centration of the beam or to the beam size- the splitting angle will be determined only by the design and the laser wavelength.

Unlike a polarizing plate beam splitter, a diffractive beam splitter is polarization insensitive, operating equally well for all polarization states, as it utilizes only the scalar diffraction of the light.

High power laser applications of diffractive beam splitters- general

A diffractive beam splitter is especially suitable to increase throughput of high-power laser micro machining applications, such as multi-channel scribing & ablation, laser multi-hole drilling and laser perforation of packages. The reasons for this are manifold:

- Beam splitter DOEs are flat, compact and have a high LDT, making them easy to integrate into the beam splitter laser system.

- Beam splitter diffractive optical elements have absolute angular accuracy, due to their semi-conductor productions processes. This is critical in sensitive applications such as solar panel contacting, where line spacing must be accurate.

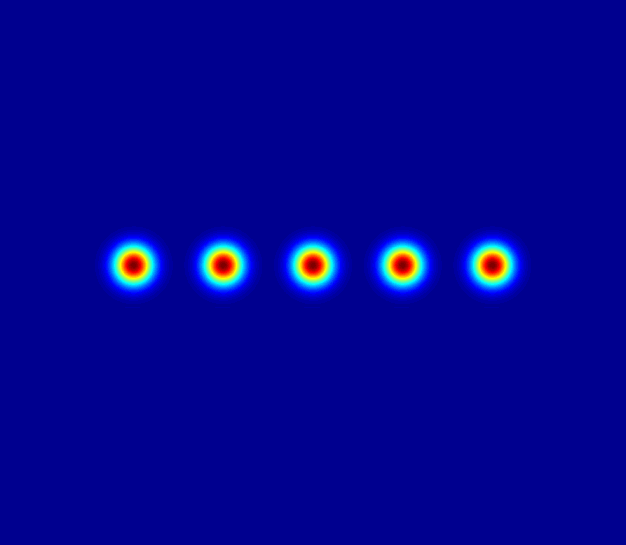

- A diffractive beam splitter lens splits the beam perfectly, with no effect on beam shape or M2 (beam quality). This is because unlike prisms and other refractive methods for producing a beam splitter, a diffractive beam splitter lens does not have sub-apertures that clip the beam. The practical meaning is that each split spot of the beam splitter has diffraction-limited size, for diffractive beam splitters.

Beam splitter use in solar panel production machines

Solar panel production often employs laser-based processes, often at 1064nm and 532nm wavelengths, operating on the silicon material of the solar cell as well as process related passivation layers.

Such processes include:

- Parallel laser scribing on silicon wafer to dice them. This process is much cleaner and faster than mechanical dicing methods, and by integrating a beam splitter DOE into the system, multiple scribe lines can be created simultaneously, increasing throughput.Diffractive beam splitters can create very low but accurate angles, enabling the entire line of spots to be scanned through scanning focus optics such as F-theta lenses.

- Laser ablation for the removal of passivation layers from the back side of passivated emitter rear contact solar cells. By adding a diffractive beam splitter, multiple via holes or lines can be ablated into the passivation layer simultaneously.

- Laser drilling of through holes for Emitter Wrap Through (EWT) solar cells. For this innovative type of solar cells, many thousands of holes need to be drilled through the silicon to enable the buried emitter production. One of the most efficient ways of achieving such multi-beam processing is using a diffractive beam splitter, capable of creating arrays of >1000 spots with good uniformity.

Beam splitter use in filters and perforated package production

Another interesting application of diffractive beam splitters is laser perforation of large areas of soft materials, such as

packaging plastics and filter papers. Due to the COVID-19 situation, demand for filters and similar products has skyrocketed, boosting demand for production machines. By enabling large fields with many thousands of perforated spots with accurate separations, beam splitters allow machine builders to utilize the increasing laser power available for such processes without the need to resort to complicated multi-head machine solutions. A single DOE splitter and large field focus optics are enough to cover a large area of more than 20X20cm with a perforation pattern in a very short time, enabling high speed roll-based production schemes.

TL; DR - Q&A summary

What is a beam splitter?

A diffractive beam splitter, or Multi-spot element as it is known, is a DOE that splits an incoming beam to multiple beams with precise separations and power ratios.

What are the advantages of a diffractive beam splitter lens for industrial laser applications?

Beam splitters have absolute angular accuracy, no effect on the split beams’ quality and high LDT. They are a single, flat passive component that can create thousands of spots, as needed, with excellent phase resolution.

Where are beam splitter DOEs used in solar panel production?

Diffractive beam splitters are used for scribing and dicing of the silicon wafers, for passivation ablation, and for through hole drilling.

Where are beam splitter DOEs used in packaging and filter manufacturing?

Diffractive beam splitters are used to simultaneously perforate thousands of holes over large areas of the filter/ package material.