Laser beam shaping applications

Many different systems and processes in various fields of application benefit from the ability to modify the laser beam irradiance characteristics at the work plane. Some of these applications include industrial processes such as laser cutting, laser welding or laser micro-machining, metrology, microscopy, medical devices, military, academic research and experiments and many more.

Beam shaping may refer to different parameters of the beam including the beam phase, amplitude and polarization. Many publications present a review of laser beam shaping theory and techniques. This article is more practice oriented, and will present some unique beam shaping optics and methods proven to improve some of the more critical laser welding process parameters.

In many welding applications high powers of up to several KW are used, often demanding precise shaping of the spot on the working plane to achieve optimized process parameters such as seam angle, seam strength, throughput and HAZ (Heat Affected Zones).

Beam shaping optics solutions for laser welding

Holo/Or offers many diffractive laser beam shaping optics for the laser welding industry. Some unique diffractive diffusers custom solutions developed specifically for laser welding process optimization include:

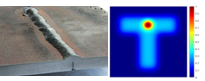

- T-shaper – A unique T-shape with a hot spot in the center allows for scanning the shape along the weld seam in butt-end joining, with optimized post-weld annealing, reducing the weld seam angle and improving weld strength.

- C-shaper – This Diffuser was found to improve width/depth ratio while welding, reduce oxidation and eliminate hot cracking by giving bubbles a place to escape the weld area.

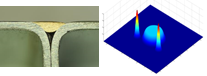

- Brazing Diffuser – This unique diffuser splits the light in 2 leading dots and one center spot. This distribution is used to melt a brazing wire between two hot-dipped galvanized plates, while preheating and cleaning both sides of the brazed seam.

Diffractive Optical Elements (DOEs) are the most accurate beam shaping solution having no angular tolerance. They are compact, flat, thin and lightweight elements with impressive beam shaping capabilities to any function that can be mathematically described, and they are passive. This quality of DOEs is mostly an advantage, however in some cases it may be a limitation, as real time adjustment of the welding spot is sometimes desired.

To address such cases, Holo/Or has developed a method to combine the accuracy of the passive DOE beam shaping with the versatility of active methods: the “Adjustable Beam Shapers”.

Adjustable beam shaping solutions for laser welding

Adjustable beam shapers are elements that contain more than one optical function on different areas of the same surface, called sub-apertures. These elements can then be assembled with either a beam switching device directing the beam to each of the areas on a desired regime, or they can be mounted on a motorized or rotation stage or as a part of a scanning system that directs the beam through different apertures.

For welding laser beam shaping applications holo/Or offers 3 variants of the adjustable beam shapers:

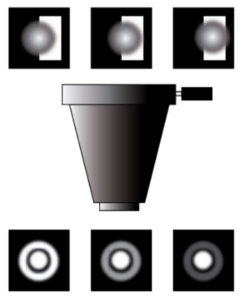

- Adjustable ring generator for high-power multimode fiber laser welding, with fiber cores 100um or above (high M^2 values) – Generates a spot (the Zero Order) within a ring. When mounted on a moving stage, one can easily change the ratio of intensity between the spot and the ring as desired, to a point where there is only the Zero Order or only the ring and anything in-between.

- scanning High Efficiency Double Spot (HEDS) beam splitter for high-power single-mode lasers with good beam quality (TEM00) – Capable of generating two beams with controlled power ratios for Dual Spot Welding. When mounted on a moving stage, one can easily change the ratio of intensity between the two spots as desired to optimize Butt-Joint welding processes.

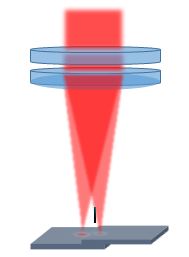

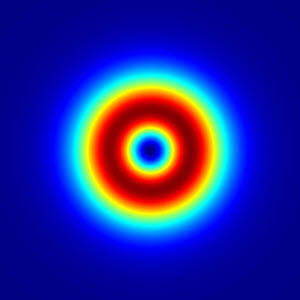

- Vortex Lens DOE – for welding with single-mode fiber lasers, the VL DOE Generates a donut shape on the work plane, providing benefits similar to ring mode fiber lasers while using standard fiber lasers. By changing the beam size propagated through the Vortex Lens DOE using a variable telescope, one can control both the inner and outer rings diameters generated thus changing the entire donut shape size.

Holo/Or can easily tailor the laser intensity to fit our customers’ application needs, both for multi-mode and single mode lasers.

TL; DR - Q&A

Is beam shaping an advantage in laser welding?

In many laser welding applications beam shaping has shown clear advantages in optimizing the welding process parameters including spatter reduction, keyhole increased stability, flatter seam angles, better seam strength and higher throughput.

What beam shaping optics is available for laser welding?

There are multiple beam shaping optics solutions from whom laser welding applications may benefit. Those who utilize the accuracy of Diffractive Optics include passive solutions such as beam splitters, ring shapers and uniquely shaped diffusers, as well as adjustable solutions such as Holo/Or’s adjustable ring shaper, the scanning HEDS beam splitter or a vortex lens DOE.

Can Diffractive Optics be used in an active shaping solution?

There are some options to utilize the advantages of Diffractive Optics in an active or semi-active shaping solution: by assembling a DOE with multiple designs in different areas with a beam switcher device, a scanner or mounting the DOE on a stage to change the location of the beam on the different apertures, one can actively adjust the generated beam shape.