Background: Solar cell production using lasers and beam shapers

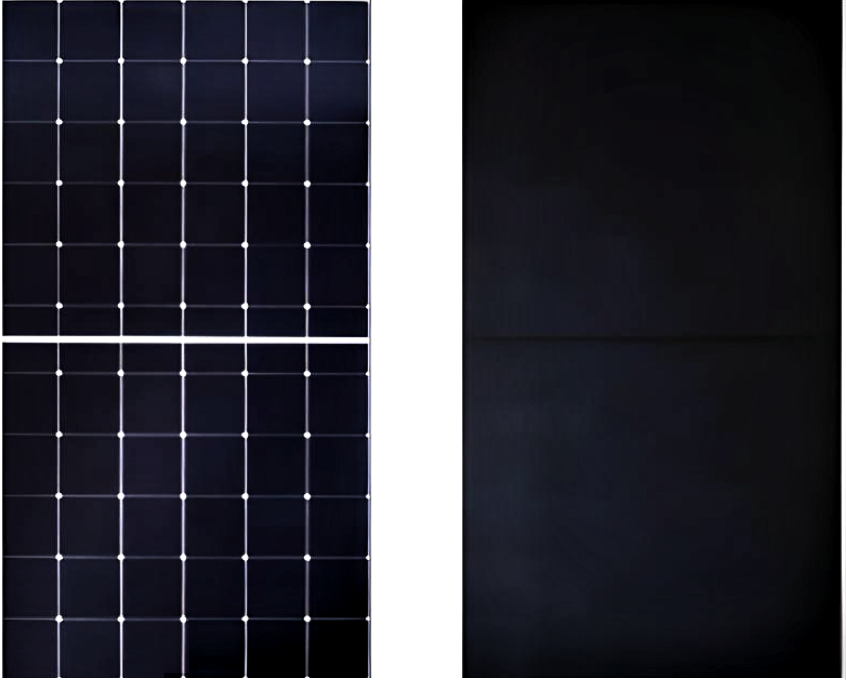

Lasers have been widely used for the production of traditional solar cells such as PERC type PV cells. The laser is used to open the oxidation layers on the backside in what is known as the LCO process (Laser Contact Opening), often employing top hat beam shaping to obtain a uniform ablation profile with fixed width. In recent years, PERC solar cells are in the process of being replaced by higher efficiency alternatives such as IBC and TOPCon PV cells. In this article, we will show how these new technologies can benefit from laser processing using precisely shaped spots.Laser processes used IBC and TOPCon PV production

IBC solar cells employ an interdigitated back contacting, thus avoiding metallization on the front surface and increasing efficiency. This scheme requires even more precision in the placement of metallization contacts compared to PERC, as the negative and positive contacts are interlaced in a finger-like pattern. Thus, LCO in IBC must be done with precise laser spot shapes with excellent uniformity and spot size stability. TOPcon PV cells utilize a thin passivation layer at the back surface, followed by a poly silicon thin layer capped by Silicon Nitride. In this configuration, the metal contacts must penetrate the cap and the poly silicon, and reach a precise depth inside the passivation to enable an optimal tunneling behavior- least recombination of charge carriers with maximal extracted current. This requires a high precision laser ablation process with excellent uniformity of the flat top laser spot over the ablation channel, to prevent uneven passivation thickness in the contact area.Top Hat beam shapers- what are they and how do they work?

Top hat beam shapers are single, passive, optical components that can change the shape of a laser spot to a flat top, uniform energy distribution of any desired shape. Typically inserted before a scanner and F-theta lens setup, the Top Hat shaper creates a uniform flat top spot at the system focus. Typically, laser beam shapers for PV applications are diffractive, using a digitized phase structure to achieve very accurate shapes of the order of tens to hundreds of microns.

Why Top Hat Beam shaping is critical in IBC/ TOPcon LCO processes

Top hat beam profiles are generally used for two main stages in the manufacturing of solar panels: LCO, where the laser energy in the flat top spot used for ablation must be uniform to prevent damage to the next layers in the PV structure and achieve consistent contact width. Laser selective doping, such as boron doping, where the laser melts the silicon near the contacts, allowing boron ions from some source (such as borosilicate glass) to diffuse into it. This reduces contact resistance and recombination losses. Other process used in IBC PV include laser contact firing, where the metal contacts are heated and melted to improve the ohmic contact with the silicon, reducing resistance. All off above mentioned PV laser processes benefit from a precise flat top laser spot created by top hat beam shapers.Advantaged of single element top hat beam shapers for PV production

• Easy to integrate into scanner+ F-theta setups • Sharp shaping- flat top spot can be as small as 1.5 diffraction limits • Asymmetric defocus behavior- can be designed to spread after the Top hat plane, to avoid damage to the next PV layers. • High stability and no thermal lensing- typically made of thin fused silica windows.Summary

Top Hat beam shapers, and especially diffractive beam shapers, have been a critical component in the production of PERC PV solar cells. With the shift to newer PV architectures, new laser processes using flat top beam shaping are being introduced, in addition to the well-known LCO process. Top hat beam shapers offer accuracy, precise defocus behavior and easy customization of the spot shape, all major advantages in PV laser-based production processes.TL; DR – Q&A SUMMARY

What are the new types of PV solar cells?

The new types currently becoming standard are Interlaced back contact (IBC) and Tunneling Oxide Passivated Contact (TOPCon)

How are lasers used in PV production?

Lasers are used in Laser contact opening, Laser selective doping and IBC contact firing, as well as for other applications such as edge isolation and dicing.

What are top hat beam shapers?

Top hat beam shapers are passive optical components that shape the spot into a flat top shape with pre-defined dimensions. Rectangles are often preferred in PV manufacturing.

What are the advantages of using Top hat beam shaping for PV production?

Top hat beam shaping improves LCO By allowing better, sharper edged, ablation of the trenches with stable width, and less chance of damage to underlying layers. For Contact Doping, uniform illumination ensures uniform doping over the contact area.