In this article, we review optical inspection and sensing systems where the illumination is a laser source that is focused by the same objective as the objective used for imaging the surface, known as beam splitter microscope imaging systems. We review the way diffractive beam splitters and beam shapers are used in such systems and how to specify and integrate them in such setups.

Introduction: What are beam splitter microscope imaging systems?

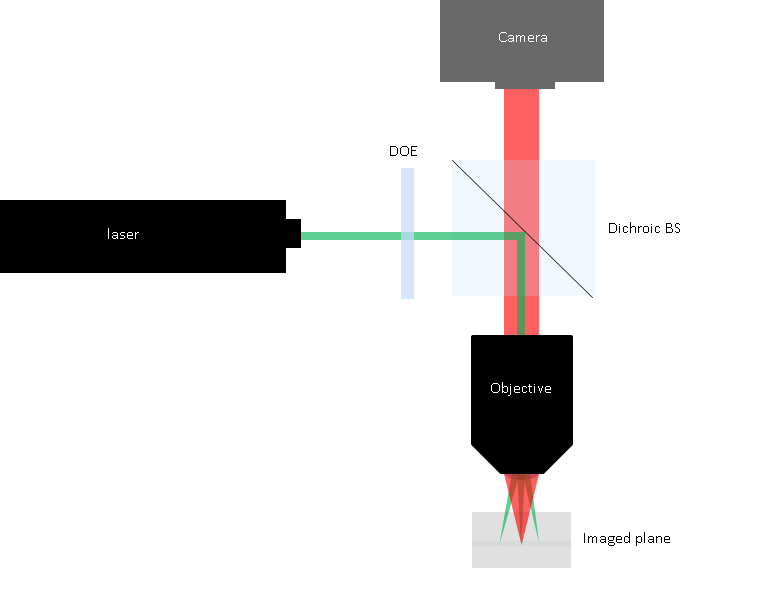

Many optical systems for various applications, including wafer inspection, cytometry, and defect analysis utilize an optical setup known as the beam splitter microscope setup. In such a setup, the optical system has two arms that share the same focus optics (typically an objective):

- the first arm is the illumination arm, where laser light is collimated and then directed through the objective to the surface to be imaged.

- The second arm is the imaging arm, where light scattering, or fluorescence induced by the illumination is collected by the objective and other optics (eyepiece/ tube lens) and imaged to a sensor/ camera.

These two arms are typically combined using a dichroic beam splitter cube, a dichroic beam splitter window or other similar beam splitter optics.

Holo/Or is often approached by customers with such setup requiring our support in integrating diffractive beam splitter or beam shapers into the imaging system. In this short article, we review the best way to do this for most typical cases.

Understanding Diffractive Beam Splitters and Diffractive beam shapers

Diffractive beam splitters are optical transmissive optical elements that employ diffraction to split an incoming laser beam into multiple discrete spots. Diffractive beam splitter optics can create any array of spots, including large 2D arrays of spots with equal separations and uniform intensity. They do this by having a relief with a fixed pitch on their surface that creates a controlled delay of the laser light going through the DOE, resulting in diffraction.

A custom beam splitter can generate laser spots with any number, position, and intensity, allowing for high accuracy detection in applications such as STED, cytometry, or wafer inspection.

Diffractive beam shapers change the input laser into a shape with flat-top intensity, including line, rectangle and round shapes, making them highly useful for inspection illumination for small feature detection.

How to specify and integrate diffractive optics in beam splitter microscope systems?

When attempting to achieve a tailored illumination profile, the type of the laser and the optical system are critical. To tailor a beam splitter to a certain illumination system, please inform Holo/Or of the wavelength, the M2 (single mode/ multi mode laser type), and the laser beam diameter, as well as specifying the objective EFL and CA, and the desired target pattern for the custom beam splitter or shaper.

In general, the correct placement of the DOE is in the illumination arm just before the dichroic beam splitter. The exact position is typically not critical, as DOE are angular thus will generate the same pattern at the work plane regardless of position, assuming the objective lens is infinity corrected.

Typical beam shaping cases for microscopy based optical systems.

For beam splitters, some typical laser beam splitters application in microscopy setups include:

- Generating a line or grid of spots to serve as a real time distance gauge. The absolute precision of diffractive beam splitter angles is highly useful in this application.

- Creating an array of donut shaped spots and a corresponding array of gaussian depletion spots, to do STED over many spots simultaneously, rather than scanning spot by spot.

For beam shapers, some typical application include:

- Flat top line generation, sometimes combined with laser beam splitting to generate several lines. These illumination profiles are useful in cytometry (to make sure all cell get the same fluorescence excitation), as well as in defect inspection of a rotating surface.

- Flat top round field illumination- to generate a uniform signal from the entire field of the objective. Often used in applications where the surface is scanned using stage movement, where the flat top illumination profile makes stitching easier.

Conclusion

Beam splitter microscope optical setups are common in many applications, from life science to wafer inspection in semiconductor industries. The use of diffractive beam splitter and beam shapers in such applications can increase speed and detection quality by tailoring the illumination to the application. Correct use of bam splitters in beam splitter microscopy system requires positioning the Doe on the illumination arm, as well as designing them according to the optical system properties, including laser and objective specs.

TL;DR:

What are beam splitter microscope setups?

Beam splitter microscope optical setups are optical setups where the same objective is used to both illuminate the imaged field and to image it back to a camera or sensor.

What are diffractive beam shaping and splitting optics ?

Diffractive beam splitter and beam shapers are passive components that can change the illumination pattern of lasers, tailoring it to fit the application .

How do you integrate DOE into a beam splitter microscope setup?

In general, the DOE is inserted in the illumination are, just before the dichroic beam splitter. To design a custom beam splitter or shaper for such a setup, the optical system, including laser and objective, should be fully specified.

what are some typical applications of beam splitters and diffractive beam shapers in beam splitter microscope setups?

Typical applications include STED, cytometry, and defect inspection.