Flexishaper beam shaper for controlled adjustable ring-to-spot ratio to increase high-powered laser welding speed

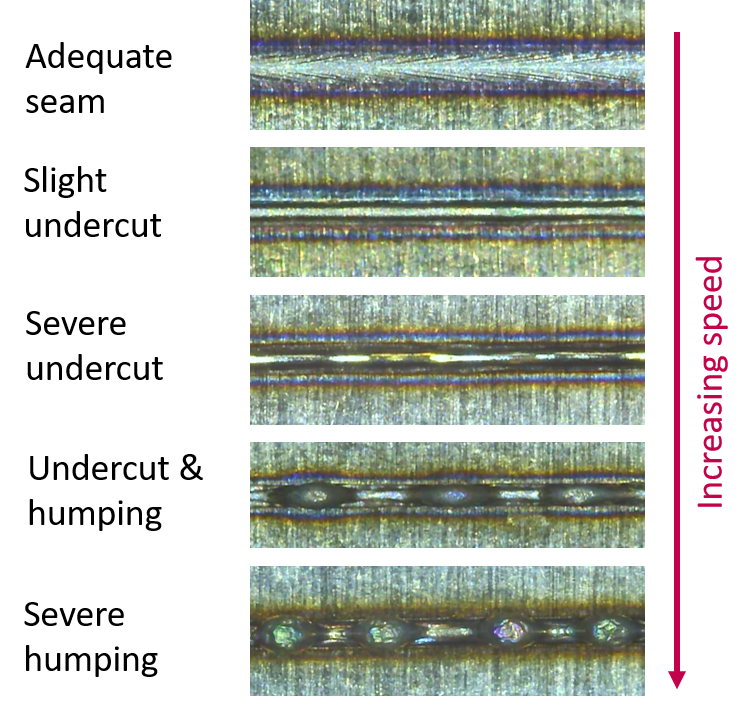

With Recent increase in the availability of high-powered NIR fiber lasers at affordable costs, power is practically no longer the limiting factor of laser welding process speed. Instead, other physical phenomena such as spattering, undercut, humping and weld porosity become dominant at high weld speed. These phenomena have been shown to be substantially reduced when using a special illumination profile consisting of a concentric ring and spot. However, the optimal power ratio between the spot and the ring differs for different welding process parameters and different system setups, and so an adjustable ring-to-spot ratio enables the system manufacturer to find the optimal work point for each process.

Flexishaper – real measurements of lab demo

In order to address this demand HOLO/OR launched Flexishaper beam shaping optical module for controlled adjustable ring-to-spot ratio. Flexishaper is a diffractive-shaping solution which consists of two identical diffractive optical elements (DOEs) placed on the same optical axis which, when rotated against one another can shape the beam propagated through them from 100% of the power in the central spot to ~80% of the power at the surrounding ring with almost no energy at the center, with a continuous full range control of the power ratio in between these states.

These passive DOEs enjoy the high LDT and extreme angular accuracy of all HOLO/OR’s products and are suitable for all high-powered laser welding application. See our LDT report.

Flexishaper DOEs can easily be installed into off-the-shelf manual or motorized rotation mounts to create an optical module. This module can be integrated in multiple configurations into the optical axis requiring no high NA or other costly optics different from the standard laser welding optics. The Flexishaper™ pair can be used with both single mode and multi-mode lasers, and can be adapted for large beams typically used with multi-kW lasers, thus enabling a large range of macro and micro-welding processes.

Once the optimal ratio for the process has been found, the module can be replaced with a single static DOE tailored to generate the exact needed ratio, providing a cost-effective solution at larger machine series.

Flexishaper concept for Adjustable ring-to-spot shaping was first introduced by HOLO/OR in a scholary article on 2019. It was then improved to the rotational module form and released on 2021.

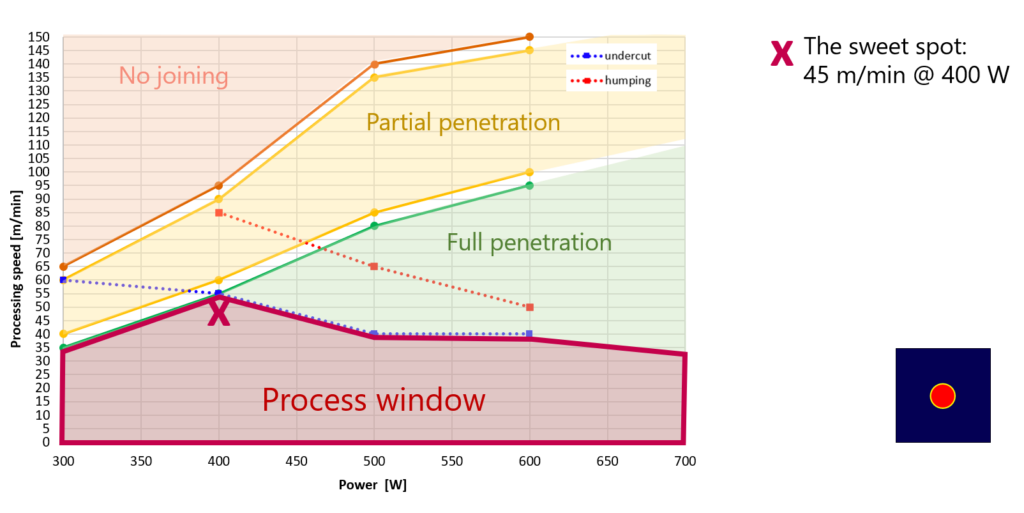

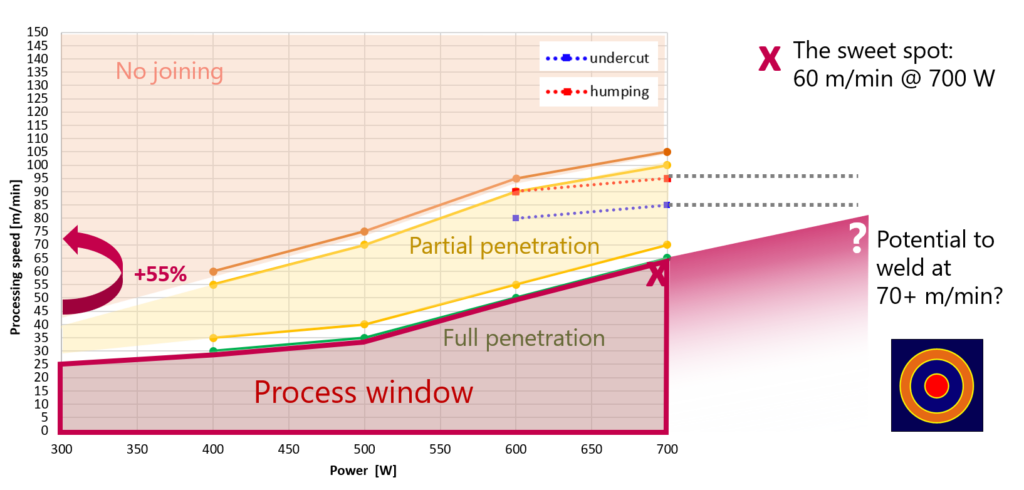

The module form was tested and validated in cooperation with HOLO/OR’s sister companies SCANLAB and BLACKBIRD for Single-Mode high-speed foil laser welding, producing an impressive increase of >30% in weld speed with up to 700W, and with potential to reach >55% increase with higher laser power approaching the 1 kW for welding an overlap of two 100 µm stainless steel sheets.

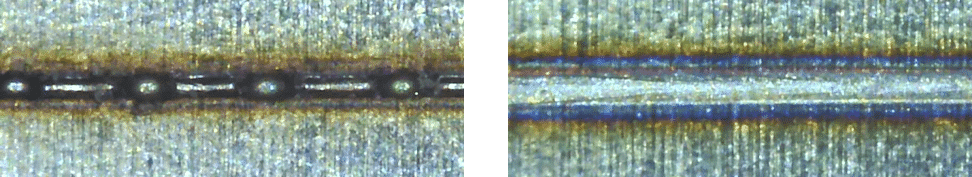

Flexishaper concept validation with SCANLAB and BLACKBIRD: Left – SM Gaussian spot welding without Flexishaper ; Right – SM laser with Flexishaper concentric ring and spot beam shaper

SPECIFICATION RANGE

| Illumination pattern | Central spot with surrounding concentric ring, adjustable controlled power ratio between ring and spot |

| Ring angle | 0.6-8 mRad (150-2000um ring size with focus lens EFL=255mm typical) |

| Wavelengths | 515nm, 532nm, 910-1080nm other by request |

| Input beam diameter after collimator (1/e^-2) | 6-30 mm, others by request |

| Laser mode | SM or MM |

| Polarization | Not sensitive |

| DOE Material | UV grade fused silica |

| DOE Dimensions | 25.4mm, 50.8mm up to 150mm diameter (square or round) |

| DOE thickness | 1.0-3.0 mm |

| Distance between DOEs | < 4 mm |

| Efficiency | From 80 % (maximum to ring) to 98 % (maximum to spot) |

| Full cycle rotation range adjustment | 15 degrees, other possible by request |

| Adjustment method | Manual |

| Coating | AR/AR |

Standard Flexishaper Elements

*Two Flexishaper elements are required to achieve the adjustable optical performance, i.e. below elements must be ordered as a pair.

| Add to Quote | |||||||

| Add to Quote | |||||||

| CU-345-I-Y-A | 1064 | 0.675 | 0.5-100% | Window* | 25.4 [mm] diameter x 3 [mm] thickness | Add to Quote | |

| CU-346-I-Y-A | 1064 | 2.0006 | 0.5-100% | Window* | 50.8[mm] diameter X 1.524[mm] thickness | Add to Quote | |

| CU-386-I-Y-A | 1064 | 2.0006 | 0.5-100% | Window* | 25.4[mm] diameter X 3[mm] thickness | Add to Quote | |

| CU-370-I-Y-A | 1064 | 0.575 | 0.5-100% | Window* | 25.4 [mm] diameter x 3 [mm] thickness | Add to Quote |

Holo/OR can provide an assembled Flexishaper DOE pair as a single manual rotation module.

Some standard module drawings below:

FL Module-001-100 for 25.4mm diameter optics

FL Module-002-100 for 50.8mm diameter optics

Any CU flexishaper element can be mounted into a module, contact us for a quote.

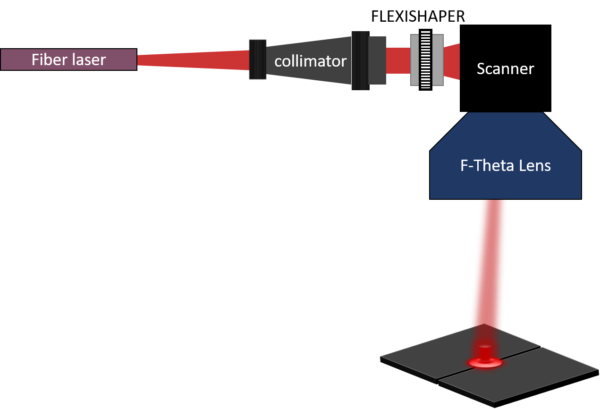

Typical installation Setup

Custom Flexishaper DOE

Holo/Or can easily tailor the pattern to fit customers’ application needs and laser power. If you are interested in custom DOEs, please contact us providing the following data:

- Work distance and requested output size at working distance

- Wavelength

- Beam definition (diameter, input mode, divergence)

- DOE dimension – if some specific values are needed

- Quantity for samples and serial production